Predictive maintenance is a proactive approach to equipment maintenance that uses data and analytics to predict when a machine is likely to fail. By leveraging Big Data, organizations can analyze vast amounts of historical and real-time data to identify patterns and trends that indicate potential equipment issues. This allows businesses to schedule maintenance tasks in advance, reducing downtime and minimizing costly repairs. In this article, we will delve into the key components of using Big Data for predictive maintenance and the benefits it brings to industries across the board.

In today’s fast-paced industrial environment, companies are continuously seeking ways to enhance efficiency and reduce downtime. One powerful approach that has emerged is leveraging big data analytics for predictive maintenance. This technique not only helps in identifying potential issues before they escalate but also significantly reduces maintenance costs and improves overall equipment effectiveness. This article will guide you through the steps involved in performing predictive maintenance using big data.

1. Understanding Predictive Maintenance

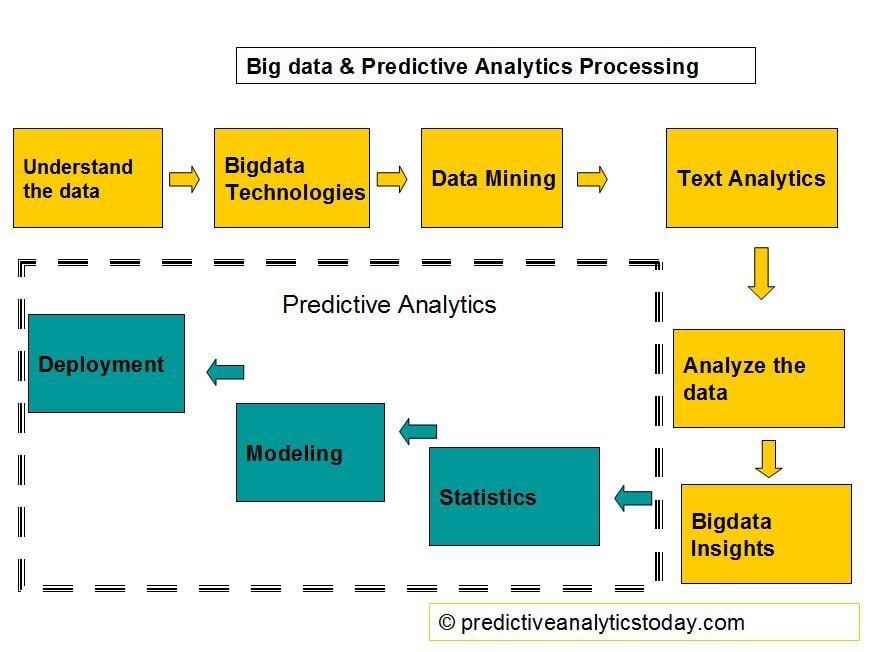

Predictive maintenance involves using data analysis tools and techniques to predict when equipment failure might occur. By utilizing historical data, sensors, and real-time analytics, businesses can schedule maintenance interventions before any faults turn into costly downtimes. This contrasts with traditional maintenance approaches, such as reactive maintenance, where repairs occur only after a failure.

2. The Role of Big Data in Predictive Maintenance

Big data plays a critical role in predictive maintenance through the collection and analysis of vast amounts of data generated by various equipment. The integration of Internet of Things (IoT) devices allows for real-time monitoring of equipment conditions. The data collected can include:

- Operational data (temperature, pressure, vibration)

- Historical performance data

- Service and maintenance logs

- Environmental conditions

3. Steps to Implement Predictive Maintenance Using Big Data

3.1. Data Collection

The first step in predictive maintenance is to achieve comprehensive data collection. This involves implementing the following:

- IoT Sensors: Install sensors on machinery to monitor various operational metrics.

- Data Integration: Use an integrated system to collect data from different sources, such as legacy systems, modern machines, and external environments.

3.2. Data Storage

Proper data storage solutions are essential to manage and analyze the collected data efficiently. Consider the following:

- Cloud Storage: Utilize cloud solutions for scalability and accessibility to large datasets.

- NoSQL Databases: Implement NoSQL databases like MongoDB or Cassandra for unstructured data storage, which is common in IoT environments.

3.3. Data Processing

Processing the data is crucial to convert raw data into valuable insights. This step may involve:

- Data Cleaning: Remove inaccuracies and irrelevant information from your datasets.

- Data Normalization: Standardize data formats for consistent analysis.

- Big Data Tools: Employ tools like Apache Hadoop or Spark for processing big data efficiently.

3.4. Data Analysis

Once the data is processed, analytical methods will provide insights into the equipment’s performance. Techniques include:

- Descriptive Analytics: Understand historical performance to identify trends and patterns.

- Predictive Analytics: Use statistical models and machine learning algorithms to forecast potential equipment failures.

- Prescriptive Analytics: Suggest maintenance actions based on predictive insights.

3.5. Machine Learning Models

To implement effective predictive maintenance, machine learning models play a pivotal role. Some popular models to consider are:

- Regression Analysis: Used for predicting continuous outcomes like remaining useful life (RUL).

- Classification Algorithms: Help classify equipment conditions (e.g., Healthy, Needs Maintenance, Critical).

- Time Series Analysis: Models such as ARIMA can forecast future equipment performance based on historical data.

3.6. Visualization Tools

Transforming complex data into understandable visual formats is essential for effective decisions. Visualization tools can include:

- Dashboards: Tools like Tableau or Power BI can provide real-time insights through dynamic dashboards.

- Alerts and Notifications: Setting up alert systems to notify maintenance teams about potential failures or anomalies.

4. Implementing a Predictive Maintenance Strategy

Once the analytical processes are in place, implement a predictive maintenance strategy by following these guidelines:

4.1. Define Maintenance Objectives

Establish clear objectives for your predictive maintenance program, such as reducing downtime by a specific percentage or optimizing maintenance schedules.

4.2. Pilot Program

Before full-scale implementation, conduct a pilot program using a limited set of equipment. This will help fine-tune your processes and identify potential challenges.

4.3. Continuous Improvement

Regularly monitor the outcomes of your predictive maintenance approach. Gathering feedback from the maintenance teams will assist in refining the models and improving the system’s accuracy over time.

5. Technology and Tools for Predictive Maintenance

Choosing the right technology and tools is critical for successfully implementing predictive maintenance. Some notable tools and platforms include:

- IBM Maximo: An enterprise asset management tool with powerful analytics capabilities.

- Microsoft Azure IoT: A complete IoT platform for connecting devices and analyzing data.

- SAP Predictive Maintenance and Service: Provides real-time insights and predictive capabilities for business processes.

6. Challenges in Predictive Maintenance

While predictive maintenance offers numerous benefits, there are challenges that organizations must overcome, such as:

- Data Privacy: Ensuring that sensitive data from IoT devices is secured from breaches.

- Integration Issues: Difficulty in integrating new predictive maintenance systems with existing legacy systems.

- High Initial Costs: Initial investment in technologies, sensors, and training can be substantial.

7. Future of Predictive Maintenance

The landscape of predictive maintenance is continuously evolving with advancements in technology, particularly in the realm of artificial intelligence and machine learning. As tools become more sophisticated, the accuracy and reliability of predictions are expected to improve, providing even greater value to businesses.

Moreover, as the Internet of Things (IoT) expands, the volume and variety of data available for analysis will increase, allowing for more refined predictions and insights, further optimizing maintenance operations.

Organizations that invest in predictive maintenance utilizing big data will be better positioned to compete in an increasingly data-driven world, ultimately leading to enhanced operational efficiency and profitability.

Leveraging Big Data for predictive maintenance enables businesses to optimize maintenance schedules, minimize downtime, and increase operational efficiency. By harnessing the power of data analytics and machine learning algorithms, organizations can proactively address equipment failures and maximize the lifespan of their assets. Implementing a robust predictive maintenance strategy can lead to cost savings, improved productivity, and a competitive edge in today’s data-driven landscape.